gpcinc

Member

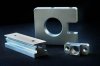

CNC Precision Turning and Milling

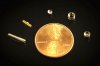

Swiss Type Precision

Automatic Screw Machining

Short Run and Prototype Machining

Contract Assembly

Micro-Deburring

We have a wide range of CNC Swiss screw machine capabilities, from short runs (1-1000 parts) to long runs (10,000+) and everything in between. We specialize in small diameter turning with both Swiss style lathes as well as our Gang Tool lathes.

For larger quantity runs, as well as wider tolerance parts, we utilize an array of Brown & Sharpe screw machines to keep production costs as competitive as possible. These machines allow us to produce quality parts with cost effective pricing to keep production here in the U.S.A. We offer many different secondary machining capabilites from drilling, tapping, threading, slotting and contract assembly. Our flexability in second operation machining helps us to better service our customers with cost effective solutions.

Our milling department utilizes vertical machining centers to accomplish precise, high speed milling, drilling, tapping and contouring. We use computer controlled accuracy to achieve conformity of even the most complex parts through a production run. Whether the job calls for flexibility on design changes, adapting to specific production needs, or anticipating inventory fluctuations, we work in close partnership with every customer to achieve quality and precision at a competitive price.

The material most common in our job shop is 304 and 347 stainless steel, but on a daily basis you’ll find us running brass, aluminum, tellurium copper, cold rolled steel, 316, 17-4, plastics, titanium and even tungsten.

We produce many prototype and short run production lots that lead to larger production runs. Our flexability in smaller lots helps to keep initial costs of production to a minimum. Most of our jobs are blanket orders. This means that the customer can get a volume discount, but receive precision machined components over 12 months, minimizing inventory. For example, you could order 12,000 pieces, but schedule them to be delivered in lots of 1,000 over the next year. Flexibility to our customer demands is one of our biggest concerns. Unmatched quality with on-time delivery is the guiding force in our attempts to maintain customer satisfaction.

Swiss Type Precision

Automatic Screw Machining

Short Run and Prototype Machining

Contract Assembly

Micro-Deburring

We have a wide range of CNC Swiss screw machine capabilities, from short runs (1-1000 parts) to long runs (10,000+) and everything in between. We specialize in small diameter turning with both Swiss style lathes as well as our Gang Tool lathes.

For larger quantity runs, as well as wider tolerance parts, we utilize an array of Brown & Sharpe screw machines to keep production costs as competitive as possible. These machines allow us to produce quality parts with cost effective pricing to keep production here in the U.S.A. We offer many different secondary machining capabilites from drilling, tapping, threading, slotting and contract assembly. Our flexability in second operation machining helps us to better service our customers with cost effective solutions.

Our milling department utilizes vertical machining centers to accomplish precise, high speed milling, drilling, tapping and contouring. We use computer controlled accuracy to achieve conformity of even the most complex parts through a production run. Whether the job calls for flexibility on design changes, adapting to specific production needs, or anticipating inventory fluctuations, we work in close partnership with every customer to achieve quality and precision at a competitive price.

The material most common in our job shop is 304 and 347 stainless steel, but on a daily basis you’ll find us running brass, aluminum, tellurium copper, cold rolled steel, 316, 17-4, plastics, titanium and even tungsten.

We produce many prototype and short run production lots that lead to larger production runs. Our flexability in smaller lots helps to keep initial costs of production to a minimum. Most of our jobs are blanket orders. This means that the customer can get a volume discount, but receive precision machined components over 12 months, minimizing inventory. For example, you could order 12,000 pieces, but schedule them to be delivered in lots of 1,000 over the next year. Flexibility to our customer demands is one of our biggest concerns. Unmatched quality with on-time delivery is the guiding force in our attempts to maintain customer satisfaction.